Introducing EzCostec’s technology.

Bio-Cellulose

“Bio Cellulose” refers to an ultra-fine sheet composed of a three-dimensional mesh structure. The raw material is created by microorganisms by naturally fermenting coconut water.

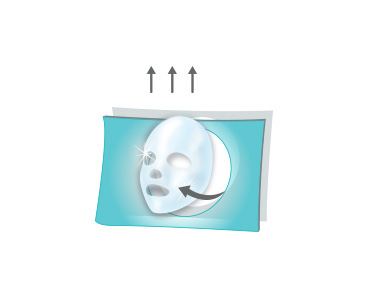

When essence is injected into bio cellulose fabric, the bio cellulose sheet thickens as it retains a large volume of essence. A sheet made this way can effectively deliver active ingredients to the skin.

Each bio cellulose sheet is thin and soft enough to be called “the second skin.” It is also highly adhesive. Bio cellulose sheets are known to have excellent soothing and moisturizing effects on skin.

Coconut from the eco-green region of Ben Tre, Vietnam

All coconut used to make EzCostec bio cellulose fabric originates from the famous eco-green region in Vietnam called Ben Tre.

Famous for little islands with lush vegetation, Ben Tre is a province in Mekong Delta in southern Vietnam. Ben Tre is also Vietnam’s largest coconut production site, covering a total of 51,000 hectares in area.

Boasting top-quality coconut grown on the fertile ground, Ben Tre yields over 400 million coconuts annually.

EzCostec top-quality products are made from such finest coconuts reaped by outstanding processors working in the best facility.

Bio-Cellulose’s Strength

-

Fermentation of Natural

Fermentation of Natural

Coconut Water -

Three-dimensional micro-fine structure with excellent adhesiveness

Three-dimensional micro-fine structure with excellent adhesiveness

-

Excellent Skin Penetration with a Fabric Free of Preservatives

Excellent Skin Penetration with a Fabric Free of Preservatives

-

Skin Cooling Effects

Skin Cooling Effects

Bio cellulose is a fabric made from fermented coconut water rich in vitamin B and C, amino acid, minerals and essential protein. It is used to make a naturally-derived high-molecular sheet developed by EzCostec’s exclusive cultivation technology.

The highly adhesive sheet with a three-dimensional mesh structure evenly delivers active ingredients of essence to the facial skin with varying textures.

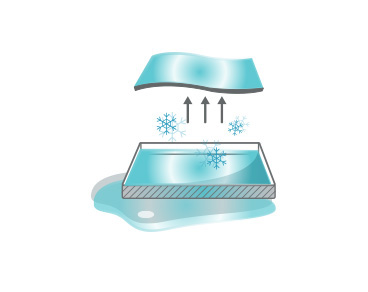

Applied with Ez-Technology Slicing Technology, each bio cellulose sheet is made into the most optimal thickness suitable for fit and adhesiveness on the skin.

The bio cellulose sheet holding essence effectively delivers active ingredients to the skin.

Made with natural fabric free of preservatives, the mask pack minimizes skin irritation.

Due to naturally cooling effects of the bio cellulose sheet, the application makes skin temperature drop more than 5℃ on average.

In addition, while the sheet on skin dries, the mask pack naturally pulls up and tightens skin.

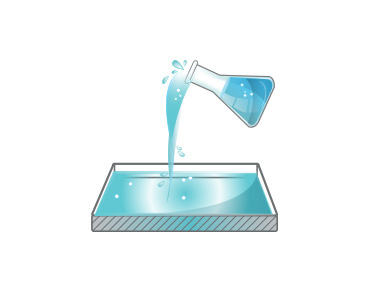

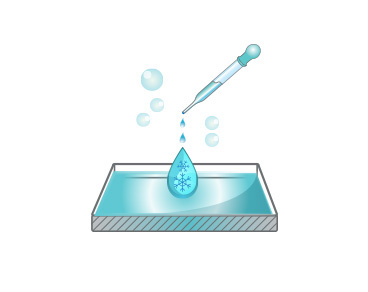

MANUFACTURING PROCESS

Acetobacter Xylnum is a naturally-derived high-molecular sheet made from natural ingredients including coconut water, which is fermented using EzCostec’s exclusive cultivation technology.

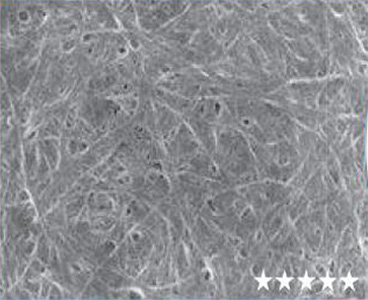

3 Dimensional Microstructure

In comparison with the spun lace sheet, the bio cellulose sheet is about 500 times thinner in diameter, and 1,000 times thinner than the pulp sheet. This property of bio cellulose makes it excellent for absorbing and retaining functional essence.

-

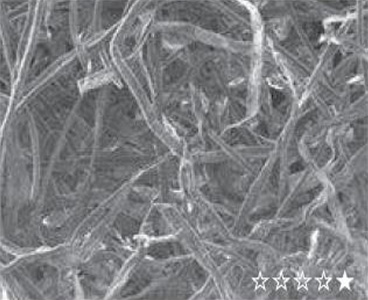

Wood-pulp

Wood-pulpDiameter of the fiber : 20,000~50,000nm

An irregular and loose structure -

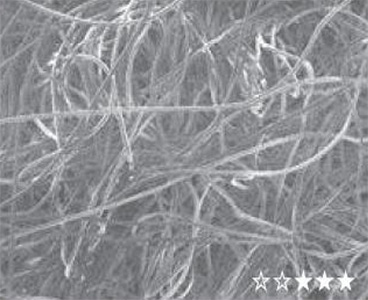

Spunlace

SpunlaceDiameter of the fiber : 10,000~15,000nm

An irregular and loose structure -

Bio-Cellulose

Bio-CelluloseDiameter of the fiber : 20~100nm

A dense three-dimensional micro-fine mesh structure

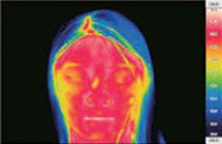

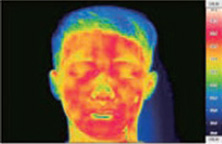

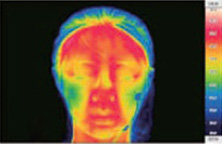

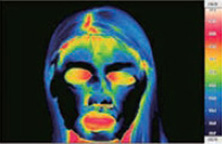

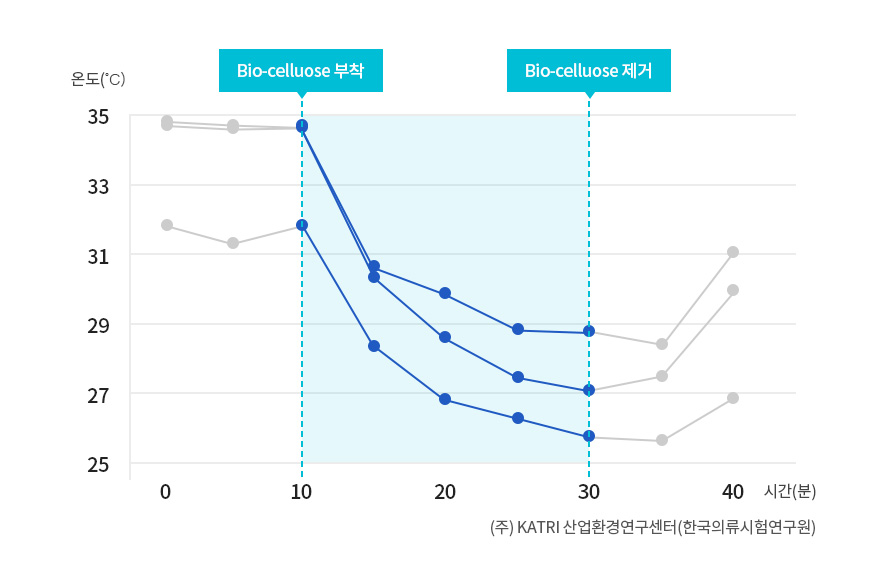

Cooling Effect & Skin Soothing

Before bio cellulose is applied, skin surface temperature is high, indicated by red is confirmed. After bio-cellulose is applied, skin temperature rapidly drops, indicated by blue is confirmed.

While a bio cellulose sheet remains intact, the skin surface temperature continues to drop about 5℃ on average, thus the product’s cooling effect is confirmed.

[ Diagram of Cooling Effects of Bio Cellulose ]

[ Diagram of Cooling Effects of Bio Cellulose ]

Strict Performance Test

- 10 harmful cosmetic substances undetected

(Lead, nickel, arsenic, mercury antimony, cadmium, dioxsane, methanol, phthalate, formaldehyde) - 6 parabens undetected

- Phynoxyethanol undetected

- Fluorescent whitening agent undetected